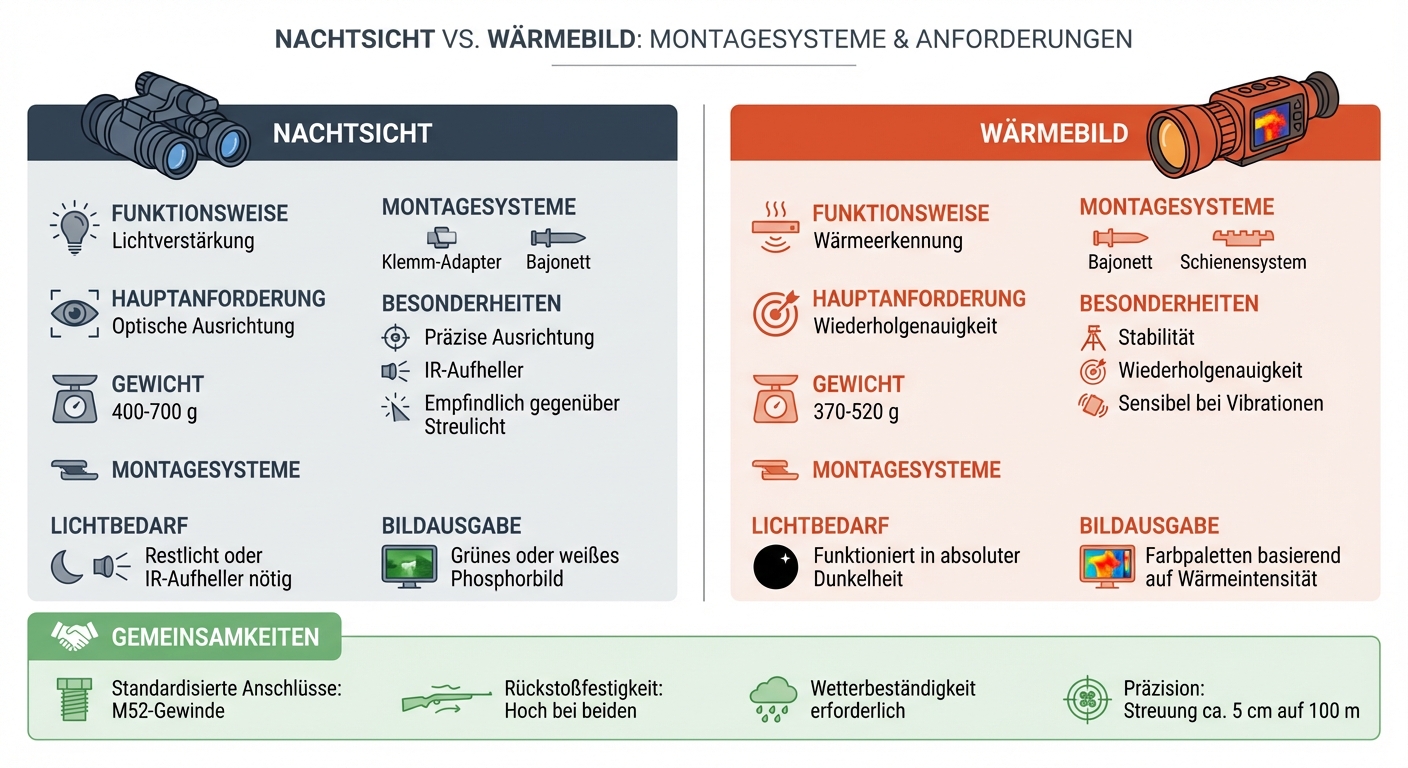

When using a night vision or thermal imaging device, choosing the right mount is crucial. Both systems require different installations to ensure precise results. Night vision devices rely on light amplification and need exact alignment as well as space for IR illuminators. Thermal imaging devices work with thermal radiation and require robust, recoil-resistant mounts that remain stable even with temperature fluctuations.

Key Points:

- Night Vision: Precise alignment, IR illuminators, sensitive to stray light.

- Thermal Imaging: Stability, repeatability, sensitive to vibrations.

- Commonalities: Standardized connections like M52 threads facilitate switching between devices.

Quick Comparison:

| Factor | Night Vision | Thermal Imaging |

|---|---|---|

| Functionality | Light amplification | Heat detection |

| Main Requirement | Optical alignment | Repeatability |

| Weight | 400–700 g | 370–520 g |

| Mounting Systems | Clamp adapters, bayonet | Bayonet, rail system |

For flexible applications, two-part bayonet systems are ideal as they allow for precise and quick mounting. If you switch between night vision and thermal imaging devices, dual-use mounts provide a practical solution. Pay attention to high-quality materials and repeatability to achieve optimal results.

Night Vision vs. Thermal Imaging Mounting Requirements Comparison

How Night Vision and Thermal Imaging Work

Night Vision: Light Amplification

Night vision devices are based on the principle of image intensification. A lens collects the available ambient light – whether from stars, the moon, or near-infrared light. This light is converted into electrons by a photocathode in an image intensifier tube. The electrons are then multiplied in a microchannel plate (MCP) made up of millions of tiny holes. Finally, the amplified electrons hit a phosphor screen, converting them into a visible image – usually in green, as the human eye perceives this color particularly well.

The differences between the generations of devices play a significant role. Older models like Gen-0 and Gen-1 often require an IR illuminator, as they are less effective at gathering residual light. Newer generations like Gen-2, Gen-3, and Gen-4 use advanced materials like gallium arsenide, providing high resolution even in extremely low light. When mounting night vision devices, especially older generations, space for IR illuminators must be planned. Regardless of the generation, however, exact adjustment of the optical axis is crucial.

In contrast to light amplification, heat detection follows a completely different approach, which also imposes different requirements on imaging and mounting.

Thermal Imaging: Heat Detection

Thermal imaging devices operate based on thermal radiation emitted by any object with a temperature above absolute zero (-273 °C). This makes them independent of ambient light or artificial light sources. The incoming thermal rays are focused onto a microbolometer sensor through special lenses made of germanium – which transmits thermal radiation better than regular glass. These sensors are highly sensitive and can detect temperature differences of just 0.01 °C, with a thermal sensitivity of under 15 mK NETD.

Since thermal imaging devices produce a digital image displayed on an internal screen, they are often heavier than digital night vision devices. For example, the Zeiss DTC 3 weighs up to 650 g. Therefore, robust and recoil-resistant mounts are necessary to ensure stability.

| Feature | Night Vision | Thermal Imaging |

|---|---|---|

| Operating Principle | Light amplification (reflected light) | Heat detection (emitted energy) |

| Light Requirement | Residual light or IR illuminator needed | Works in absolute darkness |

| Mounting Focus | Alignment with light path and IR accessories | Mechanical precision and stability |

| Image Output | Green or white phosphor image | Color palettes based on heat intensity |

These technical fundamentals are crucial for later comparing the specific mounting requirements of both systems in detail.

Briefly Explained: Night Vision Devices and Thermal Imaging Cameras for Night Hunting | Our Territory | #82

Mounting Requirements for Night Vision Devices

Night vision devices require precise mounts as their function is based on a sensitive image amplification principle. Particularly important here is the repeatability: The mount must ensure that the device takes the exact same position after being removed and reattached, so that the point of impact remains unchanged. Modern systems often rely on standardized M52 threads for collimator or reduction rings to ensure broad compatibility between different brands and adapters.

The choice between single-piece clamp adapters and two-part systems directly affects precision in use. Adapters from well-known manufacturers like Rusan or Smartclip have proven effective, but there is a risk that they may not be tightened correctly in the dark or under cramped conditions, such as in a high seat. Such mounting errors can lead to point of impact deviations. This issue has paved the way for more precise, two-part quick-release systems.

Quick-Release Systems

Two-part bayonet connections offer a clever solution: The clamp sleeve remains permanently attached to the scope, while the bayonet ring is attached to the night vision device. This ensures that the device always locks into the same, precisely repeatable position, practically eliminating misalignment.

“The advantage is that the clamp sleeve stays on the glass and the bayonet ring is on the attachment device. When you want to attach the device, it can only be locked in an exactly repeatable position.” – Venari Hunting Technology

The VENARI Duo-Connector is available in sets for €169.00 to €249.00, while individual bayonet rings start at around €50. This higher investment pays off through faster mounting and reliable point of impact – especially when frequently switching between day and night optics.

Robustness and Light Protection

In addition to precise positioning, the stability of the mount also plays an important role. A robust mount not only protects the night vision device from recoil but also from impacts. High-quality mounting systems often use magnesium housings, which are lightweight yet very durable. Additional protective measures such as dust caps (€23.00–34.00) and flip covers (approx. €28.00) are essential to protect the sensitive image intensifier tube from light and dirt. Furthermore, a good mount should allow for a dispersion of about 5 cm at 100 m to guarantee the mechanical precision of the overall system.

Mounting Requirements for Thermal Imaging Devices

The precise mounting of a thermal imaging device is crucial, as even the smallest shifts can be visible due to the highly sensitive sensors of these devices. Modern thermal imaging devices with a sensitivity of under 15 to 25 mK NETD are extremely sensitive to vibrations or positional deviations. Therefore, a stable and exact attachment is essential to keep the point of impact constant. Below, we explain how precise zeroing and stable mounting meet these requirements.

Precise Zeroing and Stability

The mount of a thermal imaging device must not only withstand recoil but also effectively absorb vibrations and mechanical stresses. High-quality devices like the Heimdall Focus 50 (approx. €3,990.00) use robust housings made of solid material to ensure stability and durability. When zeroing – for example, with heat pads at about 120 meters – a precise mount ensures that the zeroing remains permanent.

Two-part mounting systems, such as the VENARI Duo-Connector (approx. €249.00), ensure precisely defined positioning. To ensure the repeatability of the device and the mount, test shots at 100 meters should result in a dispersion of about 5 cm.

Thermal Expansion and Vibration Resistance

Temperature fluctuations in the hunting area can affect the connection between the attachment device and day optics. Single-piece clamp adapters tend to slip with inaccurate positioning, especially under changing weather conditions. Two-part systems minimize this problem through mechanical locks that function reliably regardless of external influences.

Vibrations and thermal expansions can also affect the mount. Two-part systems with precise locking rings, such as those used in Rusan adapters, ensure a secure fit without excessive tension. Integrated rail systems like the Blaser iC rail offer automatic positioning: The thermal imaging device sits perfectly aligned every time it is attached – regardless of lighting conditions or temperature fluctuations.

sbb-itb-1cfd233

Night Vision vs. Thermal Imaging: Mounting Requirements Compared

After describing the specific mounting requirements for night vision and thermal imaging devices, it is time for a direct comparison. Both types of devices impose different requirements on their mounts, which must be carefully considered.

Night vision devices primarily require a light-tight seal to keep stray light away that could affect the sensitive image intensifier tubes. Additionally, extra optical components may be necessary to optimize performance.

Thermal imaging devices, on the other hand, focus on precisely repeatable positioning. Their highly sensitive sensors, which often have a NETD (Noise Equivalent Temperature Difference) of under 15 mK, react to even minimal deviations during mounting. An advantage is the possibility of digital fine-tuning via the device menu. Models like the Heimdall Focus 50, for example, allow for the storage of up to three different zeroing profiles.

“The set attachment device retains the point of impact.” – Venari Hunting Technology

A standardized M52 connection ensures flexibility when switching adapters. Particularly practical are two-part bayonet systems like the VENARI Duo-Connector (approx. €249.00). They mechanically lock into a precisely defined position and prevent the device from misaligning – even in the dark.

Comparison Table: Central Mounting Factors

| Factor | Night Vision (Attachment Device) | Thermal Imaging (Attachment Device) |

|---|---|---|

| Main Goal of Mounting | Optical alignment & IR support | Repeatability & digital zeroing |

| Typical Weight | 400 g – 700 g | 370 g – 520 g |

| Zeroing | Mechanical precision | Digital correction & profiles |

| Recoil Resistance | High (protection of tubes) | High (protection of sensors) |

| Interface | Clamp adapter / M52 thread | Clamp or bayonet / M52 thread |

| Additional Hardware | Often requires IR illuminators | Integrated laser rangefinder |

| Weather Resistance | Standard sealing | High (resistance to thermal expansion) |

This overview highlights the different requirements and shows how mounts can be optimized for dual use to effectively support both night vision and thermal imaging devices.

Dual-Use Mounts for Both Device Types

If you want to use both night vision and thermal imaging devices, you don't necessarily have to purchase a separate mount for each device. Thanks to modern dual-use mounting systems that rely on standardized connections like the M52 thread, you can flexibly switch between different attachment devices. These systems build on the previously explained importance of the M52 standard and offer a practical solution for easily and precisely mounting devices.

The biggest advantage of such systems lies in their repeatability. High-quality mounts allow you to remove a device and later reattach it without changing the point of impact. Two-part bayonet systems are particularly popular: Here, a clamp sleeve remains permanently attached to the scope, while the attachment device is equipped with a bayonet ring. When attaching, this system ensures precise and repeatable positioning.

“A good adapter must be used in such a way that the attachment not only shoots optimally at the shooting range but can also be quickly mounted in the hide, with repeatable accuracy.” – Venari Hunting Technology

While clamp adapters require a certain degree of finesse, bayonet systems offer significantly higher reliability in terms of accuracy. Models like the VENARI Duo-Connector (approx. €249.00) solve this problem with their intuitive “Plug-and-Turn” mechanism. But how do such interchangeable mounting systems perform in practice?

Interchangeable Mounting Systems

Your choice between a clamp or bayonet system largely depends on your application area. Frequent changes between different rifles or attachment devices clearly favor a bayonet system, as it offers exact repeatability. For occasional users, a clamp adapter may be sufficient – provided that the mounting is done carefully and the device supports profile storage functions. Modern thermal imaging devices like the Heimdall Focus 50 allow for the storage of up to three zeroing profiles, so a single attachment device can be easily used on multiple weapons.

| Feature | Clamp Adapter (e.g., Rusan) | Bayonet System (e.g., Duo-Connector) |

|---|---|---|

| Mounting Speed | Slow; manual alignment needed | Very fast; “Click-and-Turn” mechanism |

| Repeatability | Medium; prone to misalignment | Absolute; mechanical stop |

| Operation in the Dark | Difficult; high risk of error | Easy; tactile locking mechanism |

| Price | Approx. €149.00 – €179.00 | From approx. €249.00 |

Both systems have their advantages and disadvantages, but the choice of the right system ultimately depends on how often you switch between devices and how important quick, error-free mounting is to you.

Mounting Solutions on Gunfinder

On Gunfinder, you will find precise mounting systems specifically designed for night vision and thermal imaging devices. A highlight is the MAKuick Duo System (€619.00–€1,889.00), which is perfectly compatible with Blaser rifles and other models. Here, we present some of the best products available on Gunfinder.

Recommended Products and Their Features

Gunfinder offers professional mounts like the Spuhr QD-Mounts and American Defense AD-RECON-Mounts, designed for maximum precision. These systems are excellent for heavy thermal optics, where stable rail mounting is crucial. Spuhr mounts are characterized by their extreme robustness and integrated spirit levels. The AD-RECON mounts feature tool-free tension adjustment and a reliable return-to-zero function.

For users of Blaser rifles, there is the Blaser Thermal Clip-on Mount, specifically designed for connecting thermal imaging attachments with scopes. Thanks to the integrated rail of the Blaser 1–7x28 iC, it allows for repeatable and precise positioning – even in complete darkness. When it comes to absolute repeatability, the VENARI Duo-Connector (from approx. €249.00) with its bayonet system is an outstanding choice.

“The mount as a link between optics and firearm ultimately determines whether the hunting weapon leads to the complete satisfaction of the hunter or shooter – or not.” – Stephan Hohn, Technical Engineer

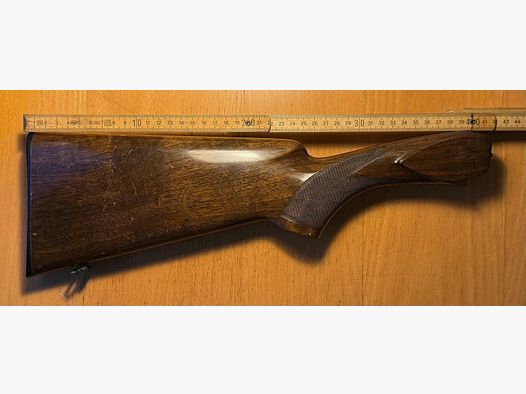

An important tip: Use a caliper to check the outer diameter of your scope. For example, a 56 mm objective may have a 62 mm housing. Also, ensure that there is at least a 3 mm gap between the adapter and the barrel.

Conclusion: Choosing the Right Mount

The choice of the right mount is crucial for the reliable function of your device. Particularly important is exact repeatability – precise, two-part bayonet systems like the VENARI Duo-Connector ensure that the point of impact remains unchanged even after frequent removal and reattachment.

For thermal imaging devices, vibration-resistant mounts are indispensable, while night vision systems benefit from quick and precise quick-detach solutions. Whether bayonet or clamp adapter – the right mount ensures that your equipment operates accurately in every situation.

On Gunfinder, you will find a wide selection of mounting systems, from classic options to specialized adapters that offer perfect fit. The platform allows you to directly compare different systems and provides secure transactions through identity verification. With practical filter functions, you can specifically select the mount that best fits your device and weapon.

FAQs

Why are two-part bayonet systems ideal for night vision and thermal imaging devices?

Two-part bayonet systems are an excellent solution for securely and quickly mounting or removing night vision or thermal imaging devices. With their precise repeatability, they ensure that the device always stays in the exact same position. This means: No annoying readjustments of the point of impact – a significant advantage, especially in the field.

These systems also score points for their reliability under difficult conditions. Whether cold, wet, or dirty – stability and calibration remain intact. This makes them ideal for hunters who frequently switch between day and night vision. On Gunfinder, you will find exactly the right bayonet systems that meaningfully complement your equipment and significantly ease your work in the field.

How do temperature fluctuations affect the mount of a thermal imaging device?

Temperature fluctuations can significantly impact the performance of a thermal imaging device mount. Materials expand at high temperatures and contract in cold. Even the smallest changes can cause the sensor to lose its calibration, affecting the image quality or range of the device.

To avoid such problems, manufacturers use materials with a low thermal expansion coefficient. These are particularly stable and are combined with robust fastening mechanisms that remain reliable even under extreme temperature changes. For hunters who often operate under changing weather conditions, a mount made of solid material with a secure locking system is indispensable. On Gunfinder, you will find a selection of mounts specifically designed for these requirements.

Why is repeatability so important when mounting night vision and thermal imaging devices?

Repeatability plays a central role as it ensures that your night vision or thermal imaging device sits exactly in the same position on the weapon after each removal and reattachment. Only then does the original calibration remain intact, and you can trust that your accuracy remains unchanged – an essential factor for precise shots, especially under difficult lighting or weather conditions.

High-quality mounts manufactured with extremely low production tolerances (in the range of tenths of millimeters) guarantee a secure fit of the device without unwanted shifting. If this accuracy is lacking, target deviations, unnecessary ammunition consumption, and a less satisfying hunting experience may occur. A carefully executed mounting saves you time and allows you to focus entirely on the hunt.