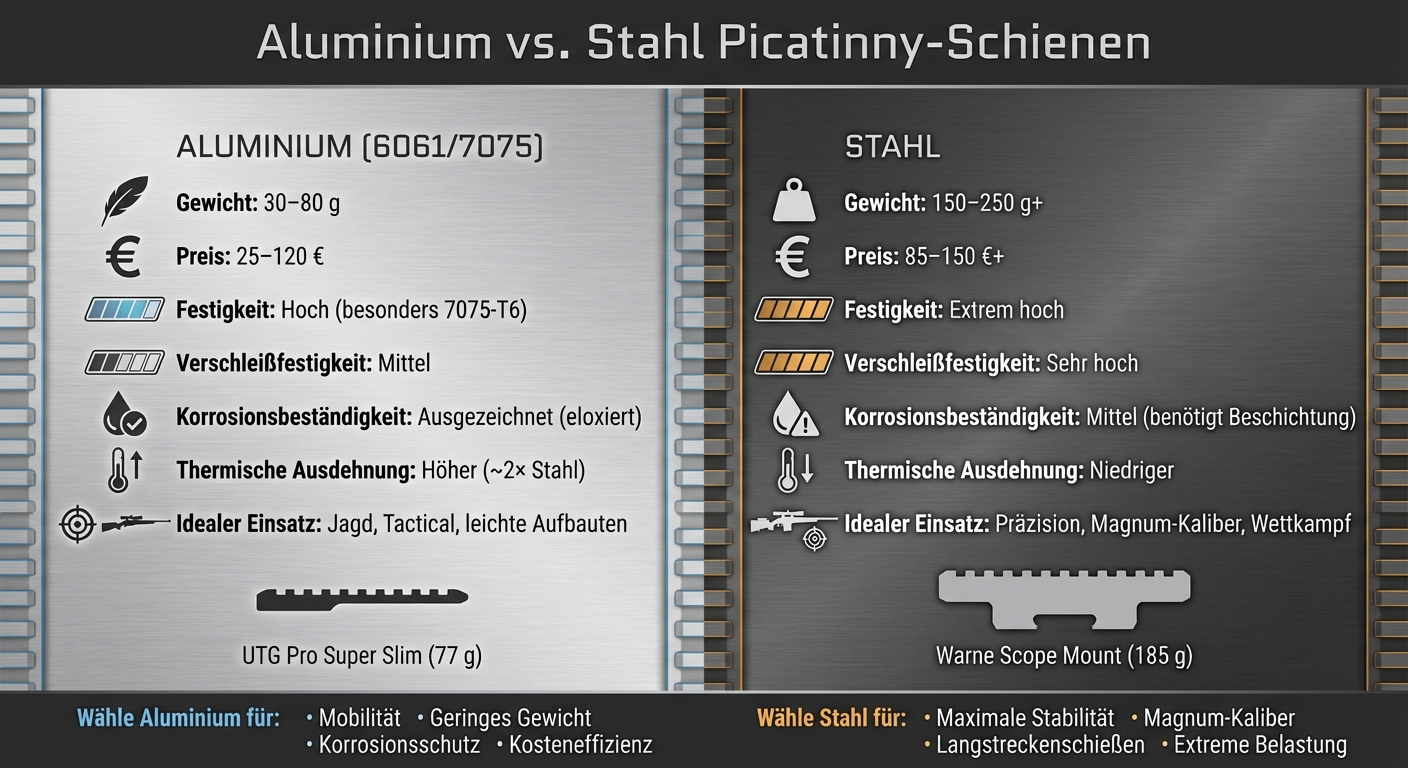

Aluminum or Steel? The choice of material for Picatinny rails depends on your intended use. Aluminum scores with low weight, corrosion resistance, and lower costs, while steel offers maximum stability, wear resistance, and precision.

Overview:

- Aluminum: Lightweight (30–80 g), rust-free, cheaper (25–120 €), ideal for hunting and lightweight setups.

- Steel: Heavier (150–250 g+), extremely stable, durable, more expensive (85–150 €+), perfect for magnum calibers and high loads.

Conclusion: Choose aluminum for mobility and lighter uses. Steel is the right choice for heavy-duty applications and maximum precision.

Advantages of Aluminum Picatinny Rails

Low Weight

Aluminum rails made from 6061-T6 or 7075-T6 offer an excellent strength-to-weight ratio. A good example is the UTG Pro Super Slim, which weighs only 77 g [2]. Manufacturers focus on "Super Slim" designs with cutouts that reduce weight without compromising stability.

Especially during longer uses, such as sitting or stalking, every gram less makes a difference. Particularly in combination with heavy attachments like thermal imaging devices, which often weigh over 1,000 g, the low weight contributes to better balance [2]. In addition to its lightness, aluminum also impresses with its resistance to external influences.

Rust Resistance

Aluminum is naturally corrosion-resistant, and hard anodizing further enhances this protection. This special surface treatment protects the rail even under heavy use and in humid environments. Additionally, many manufacturers use galvanized or zinc-nickel-coated screws to keep the mounting points rust-free.

Thanks to these properties, aluminum rails are ideal for use in changeable weather. Whether rain, snow, or high humidity – the rails remain ready for use without additional maintenance. These advantages are also reflected in an attractive price-performance ratio.

Lower Price

Aluminum rails are cheaper than steel variants because the material is easier and quicker to process [3]. Prices vary depending on quality: Polymer models like the Magpul MOE range from 15 to 25 €, standard aluminum options like the UTG Pro Super Slim cost about 35 to 45 €, and high-quality 7075-T6 models like the Warne Mountain Tech range from 75 to 120 € [2].

However, the lower price does not mean a loss of quality for most applications. Only under extreme loads, such as from heavy magnum calibers, does steel show its strength. For budget-conscious hunters, aluminum rails therefore offer a professional and cost-effective solution that meets the demands in most scenarios.

Advantages of Steel Picatinny Rails

Higher Strength and Stability

Steel Picatinny rails are specifically designed for extreme loads. The biggest advantage lies in the hardness of the material: steel is more resilient than aluminum and offers excellent protection against mechanical damage. This means that even under strong recoil or the use of steel rings, the alignment of the rail remains stable in both horizontal and vertical planes. Aluminum, on the other hand, can give way under such conditions.

“Heavy-Duty Rails... are machined from solid billet Steel... making them the top choice for heavy magnum calibers, law enforcement use, and extreme hard-use scenarios." – EGW Guns [1]

The higher rigidity of steel also ensures an absolutely flat and rigid mounting surface. This is a crucial advantage for precision shooters, as this stability forms the basis for reliable and accurate target acquisition. At the same time, it minimizes potential issues such as thermal expansion and increases the lifespan of the rail.

Lower Thermal Expansion

Another advantage of steel is its low thermal expansion coefficient of 10.8–12.5×10⁻⁶ m/(m °C), compared to aluminum at around 23×10⁻⁶ m/(m °C) [3] [5]. This property ensures that steel rails build up less stress during temperature fluctuations. This is a significant advantage for long-range shooters who rely on precision under changing weather conditions. The nearly identical thermal expansion of the rail and housing prevents mounting stresses from negatively affecting accuracy.

Outstanding Durability

Steel Picatinny rails are characterized by their exceptional durability. They are resistant to scratches, abrasion, and mechanical damage – even with frequent attachment and detachment of accessories. The precise surface remains intact, making the use of steel rings in combination with the rail particularly effective.

For professional applications where maximum stability and reliability are required, steel is the best choice. Even under extreme conditions, such as those encountered in military or police operations, steel proves to be extremely robust. These properties make steel rails the ideal solution for anyone looking for a durable and reliable mounting platform without sacrificing flexibility.

Aluminum vs. Steel: Direct Comparison

Aluminum vs. Steel Picatinny Rails Comparison: Weight, Price, and Properties

After highlighting the strengths of both materials, here comes a direct comparison to help you make the right choice for your intended use.

Both materials have their advantages – ultimately, the decision depends on what you want to use them for. Aluminum impresses with its low weight and lower costs, while steel scores with extreme stability and high wear resistance. A practical example: The UTG Pro Super Slim weighs only 77 g, while the comparable Warne Scope Mount weighs 185 g, more than twice as much [2].

Another difference lies in thermal expansion: aluminum expands about twice as much as steel with temperature changes [3]. However, in practice, this effect is usually negligible. For a 12.7 cm long rail, the difference between 0 °C and 65 °C is only 0.001 mm – not a problem for most applications [3].

“Using steel rings on an aluminum base increases the risks of the rings damaging the base over time due to recoil impulses." – Buttermilk, Long Range Hunting Forum [3]

To clarify the differences, the following table shows the key properties of both materials in comparison.

Comparison Table

| Property | Aluminum (6061/7075) | Steel |

|---|---|---|

| Weight | 30–80 g | 150–250 g+ |

| Strength | High (especially 7075-T6) | Extremely high |

| Wear Resistance | Medium (can be damaged by steel) | Very high |

| Corrosion Resistance | Excellent (anodized) | Medium (requires coating) |

| Thermal Expansion | Higher (~2× steel) | Lower |

| Price Range | 25–120 € | 85–150 €+ |

| Ideal Use | Hunting, Tactical, lightweight setups | Precision, Magnum calibers, competition |

Interestingly, high-quality rails made from 7075-T6 aluminum still offer a significant advantage in weight despite their higher costs (75–150 €) [2].

sbb-itb-1cfd233

Which Material Should You Choose?

The decision between aluminum and steel depends on your intended use. Factors such as weight, recoil, and environmental conditions play a crucial role. Choose the material that best meets your requirements.

When Aluminum is the Better Choice

Aluminum is ideal for mobile uses such as hunting or sitting. Its low weight and natural corrosion resistance make it particularly practical. It helps maintain balance, even with heavy thermal imaging devices like the Trijicon IR-HUNTER MK3 60MM (1,072 g) or the ATN ThOR 5 LRF (873 g)[2]. For most hunting or sport shooting applications, 6061-T6 aluminum offers a balanced ratio of strength to weight. Additionally, it remains resistant to corrosion even in humid environments[2].

For more demanding applications, high-strength 7075-T6 aluminum is suitable. It bridges the gap between standard aluminum and steel. An example of this is the Warne Mountain Tech, which has been rated 5.0 out of 5 stars by users for its precise CNC machining and durability[2].

When Steel is the Right Choice

Steel is the first choice when it comes to long-range shooting, heavy magnum calibers, or competitions. At distances over 600 meters or with large-caliber magnums, the maximum rigidity of steel ensures the necessary precision[1].

“Heavy-Duty Rails: Overbuilt for maximum strength and recoil resistance... the top choice for heavy magnum calibers, law enforcement use, and extreme hard-use scenarios." – EGW Guns[1]

For tactical applications and extreme loads, steel offers the highest safety. Always combine steel rails with steel rings to avoid damage from recoil impulses. However, steel rails require a protective coating in humid or salty environments to prevent corrosion[2].

A practical tip: Use a torque wrench (20 inch-pounds) and non-permanent thread lockers to ensure precise and secure mounting[1].

Conclusion

Choose aluminum if you prioritize mobility and low weight, or steel if maximum stability is required for heavy-duty applications. Aluminum impresses with its low weight, natural corrosion resistance, and attractive price. Steel, on the other hand, offers maximum rigidity, better thermal properties, and impressive load capacity – but at a higher price, ranging from 85 € to over 300 €.

In short: Aluminum excels in lightness and rust protection, while steel stands for maximum stability and durability. For hunting, mobile uses, or the use of heavy thermal imaging devices, aluminum is the more practical choice. For shots over 600 meters, magnum calibers, or competitions, steel delivers the precision and stability you need. Both materials meet the MIL-STD-1913 standard and are therefore universally compatible with your accessories.

“The Picatinny rail allows more versatility for eye relief and mounting options than other systems... It is also a stable platform that provides a rigid and flat mounting surface." – Jerry Dill, Farrell Industries Inc. [4]

The choice of material is a crucial component for your equipment. Combine aluminum rails with aluminum rings or steel rails with steel rings. Be sure to work with a torque wrench (20 inch-pounds) and blue thread locker to ensure lasting accuracy.

On Gunfinder, you will find a suitable selection of rails and optics that are ideally tailored to your intended use.

FAQs

Why are Aluminum Picatinny Rails a Good Choice for Hunting?

Aluminum Picatinny rails are particularly convincing due to their low weight. Compared to steel variants, they are up to 2.5 times lighter. This is especially noticeable when you have to carry your hunting weapon over long distances. Less weight means not only more comfort but also better balance – a clear advantage during quick movements or position changes in the field.

Another plus point is the price. Aluminum rails are usually cheaper than their steel counterparts, yet still offer sufficient stability for most hunting optics. Especially in combination with lightweight night vision or thermal imaging devices, they are a smart choice as they keep the overall weight of your equipment minimal.

For hunters who value a compact weapon, aluminum rails offer an additional advantage: they are often built flatter. This not only facilitates the mounting of optics but also ensures that your weapon remains handy. All in all, aluminum rails are a thoughtful and cost-effective option for various hunting situations.

Why are Steel Picatinny Rails Better for Magnum Calibers?

Steel is characterized by its superior strength and high surface hardness, making it particularly resilient and wear-resistant. These properties make it perfect for handling the stronger recoil forces of magnum calibers, as it can efficiently absorb and evenly distribute them.

Compared to aluminum, steel offers significantly higher load capacity over a longer period. This is especially important for powerful calibers to ensure both precision and safety in the long term.

How Does Thermal Expansion Affect the Precision of Picatinny Rails?

The thermal expansion of Picatinny rails has a direct impact on precision, as aluminum and steel respond differently to temperature changes. Aluminum rails tend to expand more with heat than steel. This can create stress at the mounting points, which in turn can lead to minimal shifts in optics and affect repeat accuracy. Steel rails, on the other hand, remain nearly dimensionally stable even with temperature fluctuations. This makes them particularly reliable during long shooting sessions or extreme weather conditions.

Another crucial factor is material compatibility. If both the rail and the receiver are made from the same material, stresses due to different expansion rates can be significantly reduced. This minimizes the risk of damage such as broken screws or deformations. For maximum precision and stability, especially under demanding conditions, steel rails are often the better choice.

If you are looking for top-quality Picatinny rails, Gunfinder offers a wide selection of models.